Strongest Connections with Max Steier

Hardly any other industry has developed as dynamically in recent years as the adhesive tape industry.

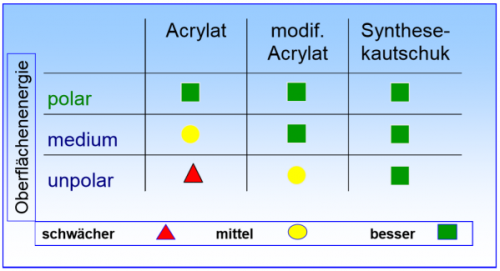

State-of-the-art lightweight materials such as fiber composites or aluminum and magnesium alloys place high demands on functional joining processes. high mechanical loads on adhesive joints, sometimes different joining partners, extensive temperature and weather resistanc, chemical resistance, UV and aging resistance, stress-balancing and process-safe processing- diverse requirements and complex tasks are the focus of constructive bonding. If materials are to be joined together, joining with die-cut parts made of self-adhesive tapes is the perfect solution, because this way the properties of the materials to be joined are completely retained.

For all occasions - High-performance self-adhesive technology for industrial use

Self-adhesive technology is more important than ever in moder joining processes. Due to its great versatility and adaptability as well as the adhesive precision, excellent results can be achieved in conjunction with the high level of cost-effectiveness. This means that perfect solutions can be achieved even in complex production processes. Self-adhesive tapes and die-cut parts are used not only in the automotive industry, but in many other industrial sectors.

- Electronics industry - fixing electronic components, e.g. controllers on circuit boards

- Plastics industry - bonding on painted and unpainted surfaces

- Mechanical engineering - connecting, assembling, fixing, e.g. attaching in front panels, nameplates and decorative strips

One step ahead - Low VOC: Low-emission interior applications

Low emissions of volatile organic compounds (VOC) and the elimination of cendensable emissions (FOG) improve the air climate in the vehicle interior and prevent health irritations and allergies. Double-sided low-VOC adhesive tapes are used as fastening solutions for carpets, decorative elements, seals, shelves, panels, seat sensors or for fixing insulation materials to the bulkhead. This means that the standard requirements of VDA 278 can be met.

Die-cut part solutions from Max Steier - Constructive bonding with success

In addition to functional adhesive tape properties, the integration of bonding processes into production processes is a high priority.

Self-adhesive tapes can be processed by hand or integrated into semi- or fully automated processes. However, with more complex process sequences, self-adhesive tapes reach their processing limits, especially with material combinations, special shapes and/or single-piece feeds. The perfect solution is die-cut parts that have the same balanced performance data as the original adhesive tape, but enable additional rationalization advantages through precisely fitting dimensions. This means that both time and cost savings can be achieved in the subsequent processing steps through advantageous handling. in addition to high-quality starting materials, the production of a usable die-cut part requires extensive product experience - Steier demonstrates its many years of know-how with comprehensive technological competence for demanding customer solutions in all industrial sectors.

Do you have any questions or need further information? Please contact us Deutsch

Deutsch

English

English

© 2022 - 2024 Max Steier GmbH & Co. KG

© 2022 - 2024 Max Steier GmbH & Co. KG